-

Phone: +86 18858673523

-

E-mail: avaxu@cnfeltingneedle.com

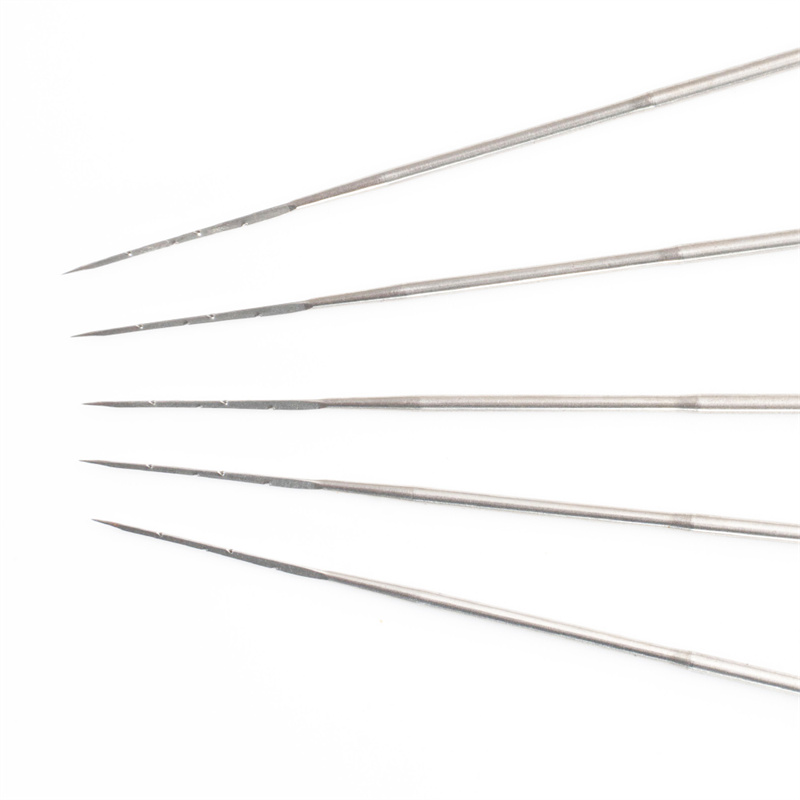

Conical Needle Used In Automotive Industry, Artificial Leather, Geotextile, Filter Felt, Etc

Product Description

Quick Details

Product name: Felting needles

Warranty: 1.5 years Applicable

Brand Name: YUXING

Use: NEEDLE LOOM

Type: NEEDLE BOARD

Production capacity: 600 million

Condition: New

Raw material: HIGH CARBON STEEL

Place of Origin: Zhejiang, China Brand

Application: For Needle nonwoven fabric

Packing: Well packed from water and damage

Packaging & Delivery

MOQ: 10000pcs

Selling Units: Multiple of 10000

Package size per batch: 32X22X10 cm

Gross weight per batch: 12.00 kg

Package Type: 500pcs into 1 plasitc box, then 10000pcs again into 1 carton box

Picture Example:

Lead Time:

|

Quantity(Pieces) |

1 - 500000 |

>500000 |

|

Est. Time(days) |

10 |

To be negotiated |

Products Show

Product Description

Gauges and diameters of Felting Needles

|

Gauge |

Shank (mm) |

Intermediate Section (mm) |

Working part Triangular blade beight

(mm) |

|

9 |

3.56 |

||

|

10 |

3.25 |

||

|

12 |

2.67 |

||

|

13 |

2.35 |

2.50 |

|

|

14 |

2.03 |

2.05 |

|

|

15 |

1.83 |

1.75 |

1.95 |

|

16 |

1.63 |

1.55 |

1.65 |

|

17 |

1.37 |

1.35 |

1.45 |

|

18 |

1.21 |

1.20 |

1.30 |

|

19 |

1.15 |

||

|

20 |

0.90 |

1.00 |

|

|

22 |

0.95 |

||

|

23 |

0.92 |

||

|

25 |

0.80 |

0.90 |

|

|

26 |

0.85 |

||

|

28 |

0.80 |

||

|

30 |

0.75 |

||

|

32 |

0.65 |

0.70 |

|

|

34 |

0.65 |

||

|

36 |

0.60 |

||

|

38 |

0.55 |

||

|

40 |

0.50 |

||

|

42 |

0.45 |

||

|

43 |

0.40 |

||

|

46 |

0.35 |

||

|

The diameter of different parts of needle is indicated by gauge. The smaller gauge meams the larger diameter. When in the working part, the cross-section height is indicated by working part gauge. The cross-section height of conical working part is measured on the position of 5mm from needle point. The other cross-section shape is measured by their height. |

|||

|

Detailed parameters of the felting needle

|

||

|

Product name |

Conical needle |

|

|

|

||

|

texture |

high-carbon steel |

|

|

colour |

bright nickel white |

|

|

Barb spacing |

regular spacing |

|

|

medium spacing |

|

|

|

close spacing |

|

|

|

frequent spacing |

|

|

|

single spacing |

|

|

|

Barb Styles |

Type F (Good penetration and hair amount, generally used as pre-piercing) |

|

|

Type G Less damage to fiber |

|

|

|

Type B Less damage to fiber |

|

|

|

Type GB Morewear-resistant during use |

|

|

|

Type L On the basis of the B type, the hook teeth are more rounded |

|

|

|

Type K(Open style needle) (Can make the hook spines with better hair quantity) |

|

|

|

Nominal length of felting needles |

4.0 inch |

|

|

3.5 inch |

|

|

|

3.0 inch |

|

|

| The above-provided sizes are standard sizes. For some particular purposes, non-standard sizes are also available. | ||

|

Standard working part lengths on felting needles |

30mm |

|

|

27mm |

|

|

| The above-provided sizes are standard sizes. For some particular purposes, non-standard sizes are also available. | ||

Application field

It is suitable for geotextile, filter cloth, linoleum machine cloth, leather cloth, automobile interiors, soundproof cotton, carpets and so on.

Automotive Interior

Soundproof Cotton

Artificial Leather

Filter Bag

Linoleum Machine Cloth

Filter Bag

Features

*The needle is composed of three foliage, the needle is perpendicular to the length of the conical triangular needle on any position of the cross section are triangular, from the needle tip to the needle waist direction of the front end of the needle gradually coarsening

*The cone Angle increases significantly from the tip to the end of the working site

*The size of the barbs on each edge is graded: the closer to the tip, the smaller the barbs are

* A plurality of barbed hooks are arranged helically on the three edges of the needles, and the tip of the barbed hook is oriented toward the direction of the tip of the needle.The conical needle can reduce the probability of breaking needle,reduce calorific value and avoid fiber damage on the premise of guaranteeing the penetration power

Advantages

*More uniform bending strength, better elasticity, better stability than standard needles (fewer broken needles), higher production speed, reduce net offset

*Less initial puncture resistance, resulting in better needle guidance, less deflection, and fewer broken needles

*The number of hooks is large, the load is not too high, the bending performance is better, and the possibility of needle breaking at the back of the working part is lower

*Better surface quality of processed products (smaller funnel-shaped dents in finalproducts)

*Less machine load

*Reduce the contamination of needle, needle plate, supporting plate and stripping plate when processing recycled fiber

Our Company

Contact Us

If you have another question, pls feel free to contact us as below:

Phone

+86 18858673523

+86 15988982293